Ningbo Xindeng Seals is a leading mechanical seal supplier in south of china, since 2002, we not only focus in making all kinds of mechanical seal, but also pay attention to the technical improvement of mechanical seals.

We often discuss with some super engineer in mechanical seal filed, and know the update of seals tech.

Below article is a good tech file to know what difference about single mechanical seal and double mechanical seal, we share this document to let more people know it.

Mechanical seals are devices that seal machines between rotating parts (shafts) and stationary parts (pump housing) and are an integral part to the pump. Their main job is to prevent the pumped product from leaking into the environment and are manufactured as single or double seals. What’s the difference between the two?

WHAT IS A SINGLE MECHANICAL SEAL?

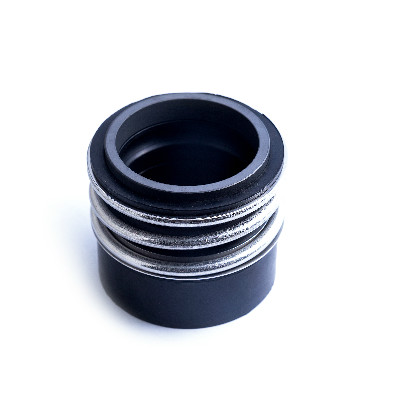

A single mechanical seal consists of two very flat surfaces that are pressed together by a spring and slide against each other. Between these two surfaces is a fluid film generated by the pumped product. This fluid film prevents the mechanical seal from touching the stationary ring. An absence of this fluid film (dry running of the pump) results in frictional heat and ultimate destruction of the mechanical seal.

Mechanical seals tend to leak a vapor from the high pressure side to the low pressure side. This fluid lubricates the seal faces and absorbs the heat generated from the associated friction, which crosses the seal faces as a liquid and vaporizes into the atmosphere. So, it’s common practice to use a single mechanical seal if the pumped product poses little to no risk to the environment.

Want More Insider Information from Crane Engineering?

WHAT IS A DOUBLE MECHANICAL SEAL?

A double mechanical seal consists of two seals arranged in a series. The inboard, or “primary seal” keeps the product contained within the pump housing. The outboard, or “secondary seal” prevents the flush liquid from leaking into the atmosphere.

Double mechanical seal

back to back

face to face

using dual seals.

Single mechanical seal

one rotary ring part

one staionary ring part.

with secondary seal part, like rubber, ptfe, fep

Double mechanical seals are offered in two arrangements:

- Back to back

- Two rotating seal rings are arranged facing away from each other. The lubricating film is generated by the barrier fluid. This arrangement is commonly found in the chemical industry. In case of leakage, the barrier liquid penetrates the product.

- Face to face

- The spring loaded rotary seal faces are arranged face to face and slide from the opposite direction to one or two stationary seal parts. This is a popular choice for the food industry, particularly for products which tend to stick. In case of leakage, the barrier liquid penetrates the product. If the product is considered “hot”, the barrier liquid acts as a cooling agent for the mechanical seal.

Double mechanical seals are commonly used in the following circumstances:

- If the fluid and its vapors are hazardous to the operator or environment, and MUST be contained

- When aggressive media are used at high pressures or temperatures

- For many polymerizing, sticky media

Post time: Jan-04-2022